FANUC Robot Teach Pendant –Simple Recognition and Safe Use

Release time:

2025-04-25 17:17

Source:

FANUC Robot Teach Pendant – Simple Recognition and Safe Use

The teach pendant is an interface between the supervisor application tool software and the user (robot). The teach pendant is connected to the control cabinet by cable. We use the teach pendant for the robot jog feed, program creation, program test execution, operation execution, and attitude confirmation.

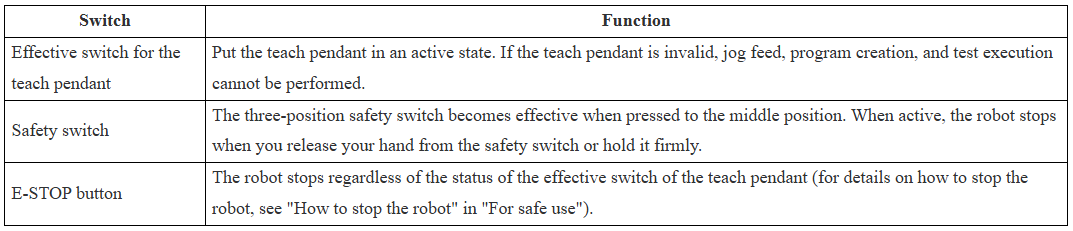

Teach pendant switch

The teach pendant has the following switches:

Table 1: Teach pendant switch

Figure 1: Teach pendant switch

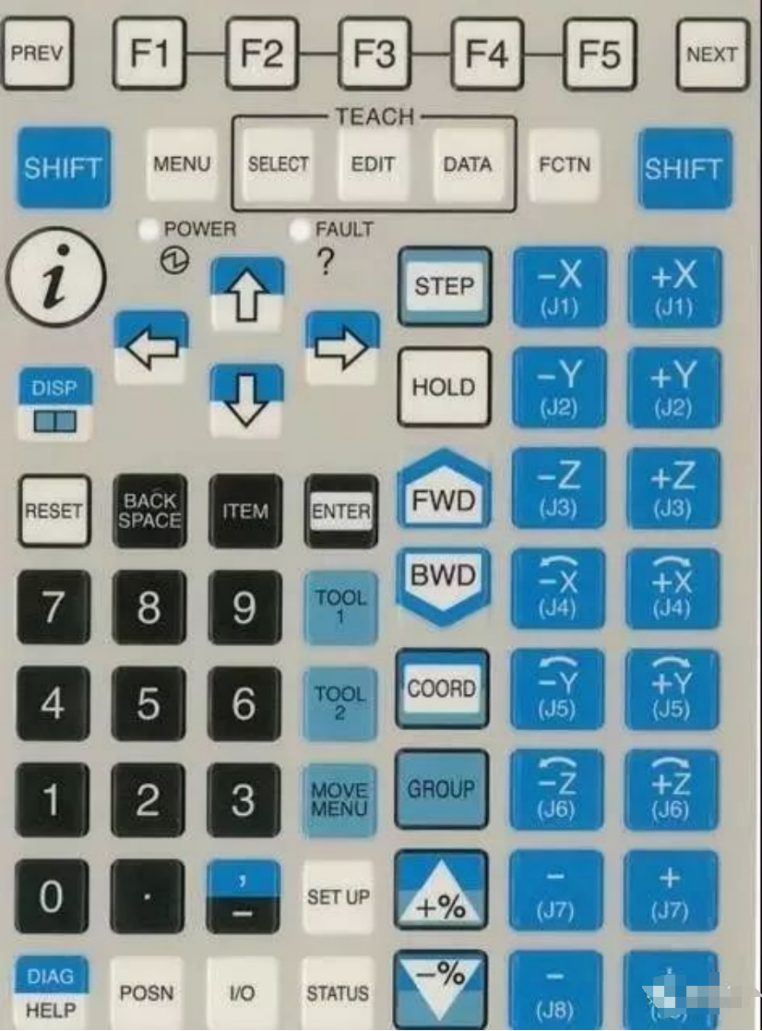

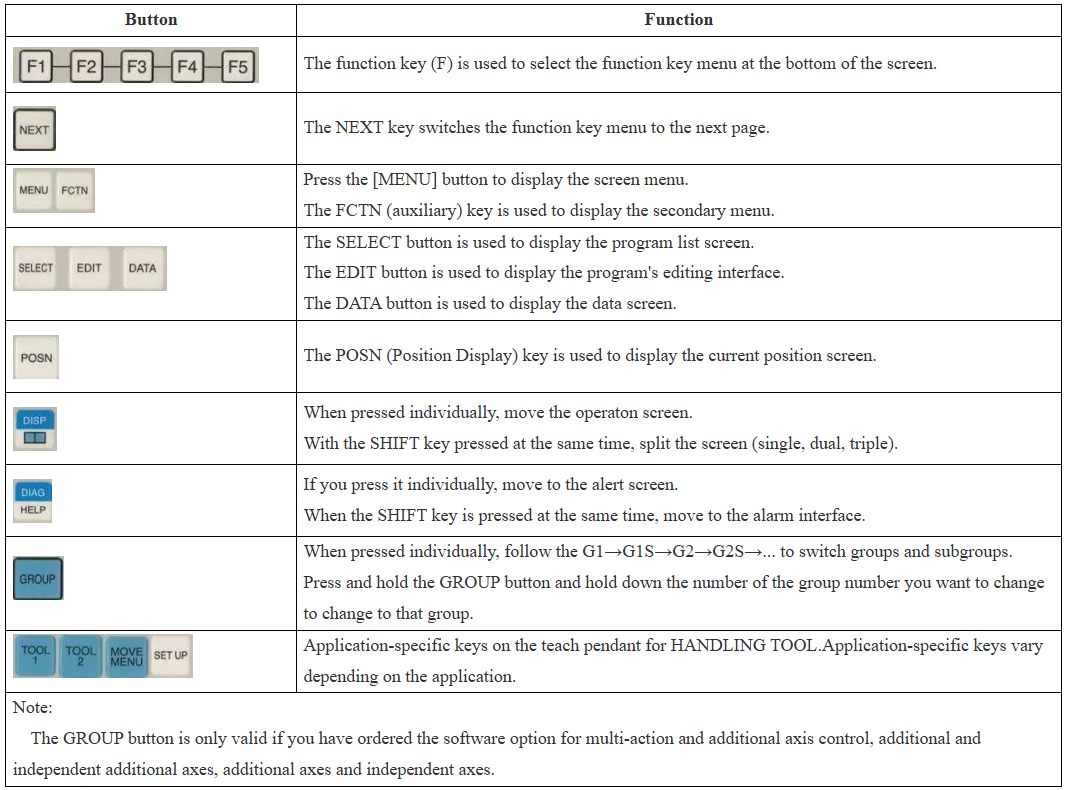

Teach pendant button

The teach pendant button consists of menu-related buttons, jog-related buttons, execution-related buttons, editing-related buttons, and other buttons.

Figure 2: Teach pendant operation keys

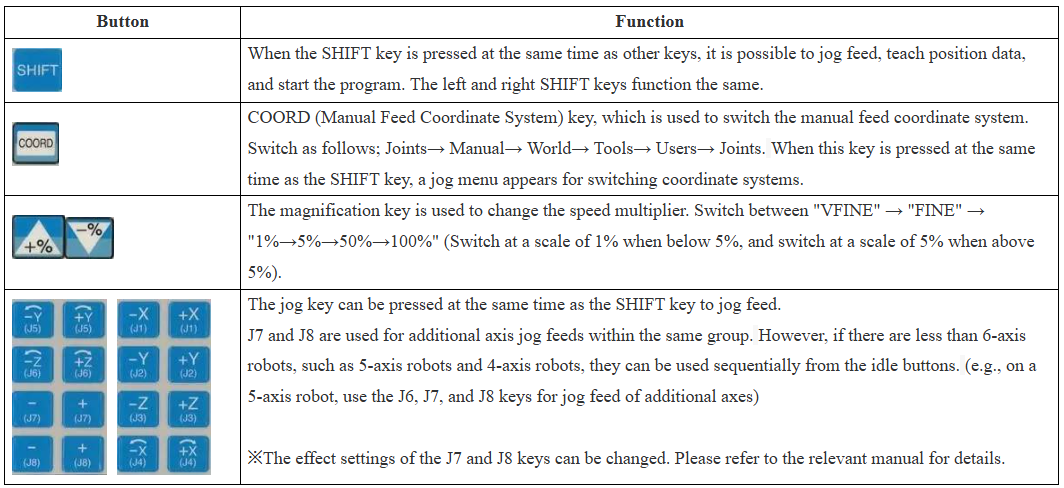

Table 2: Keys related to the application

Table 3: Keys related to jogging

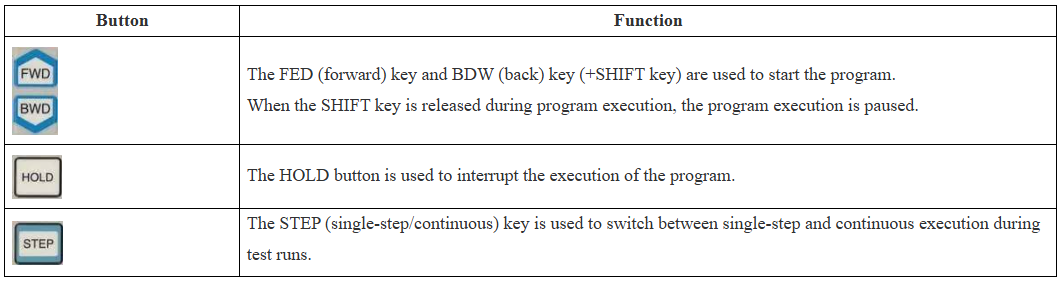

Table 4: Execution-related keys

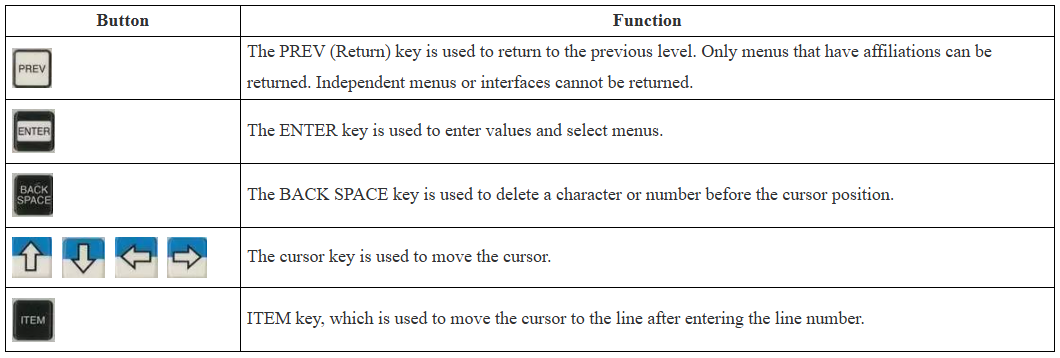

Table 5: Other buttons

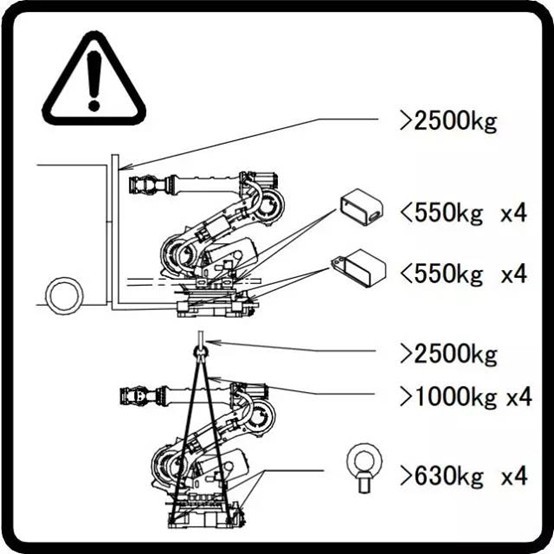

1. On the side of the J2 pedestal you will find such markings. This mark is a handling mark.

Handling markers(R-2000iB/165F,210F,250F,125L,175L,100H,150U)

When handling the robot, we should strictly follow the instructions of the handling mark. Different models have different handling marks. Please refer to the manual of the relevant aircraft for the shipping posture of each model.

In the case of the above marking, it reads as follows:

(1) In the case of forklift crane handling

Forklift cranes that can handle a weight of 2500kg or more should be used for handling. The forklift crane bracket (option) has a load resistance of 5390N (550kgf), so the total weight of the robot to be handled should be 2200kg or less.

(2) The situation of using cranes for handling.

When handling, a crane with a handling weight of more than 2500kg should be used; 4 slings with a load of more than 9800N (1000kgf) and 4 eye bolts with a load of 6174N (630kgf) or more.

2. In addition, when handling, we should also pay attention to the use of relevant designated transportation components to ensure the safety of relevant personnel and the robot body.

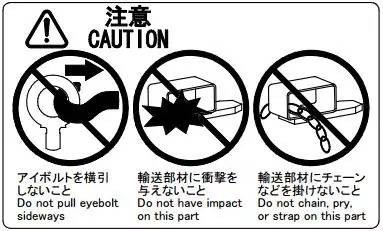

Handling attention markers

The content of the above handling attention mark is: the following matters should be paid attention to when handling the robot:

(1) Do not pull the eyebolt to the side.

(2) Do not use the jaws of forklifts, cranes, etc. to apply impact force to the conveying components.

(3) Do not attach chains, etc. to the transport member.

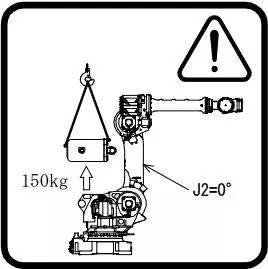

3. When we need to replace the balance adjustment unit, we should all check and strictly follow the instructions of the balance adjustment unit replacement mark.

Balance adjustment unit replacement marking(R-2000iB/165F, 210F, 185L, 250F, 125L, 175L, 100H)

In the case of the above-mentioned balance adjustment unit replacement marking, it reads as follows:

(1) The attitude of the robot should be at 0° on the J2 axis.

(2) The weight of the robot's balance adjustment unit is 150kg.

4. There is also a warning sign on the balance cylinder for a stationary disassembly.

Dismantling of the mark is prohibited

When this mark appears, we need to pay attention to the fact that there is a spring inside the balance cylinder, which is very dangerous, so do not disassemble it.

5. When we need to change the lubricating oil, we will also see such a mark:

Fat donation/fat removal marking

It tells us some precautions when refueling: remove the outlet screw before adding lubricating oil; A manual refueling pump should be used for refueling; The corresponding lubricating oil of the model should be used; Please refer to the service manual of the model for the specified lubricating oil, refueling amount and the location of the oil filler and oil outlet for the specific lubricating oil of the model.

6. Such a warning mark appears on the robot motor, body, cover or balance cylinder.

Foot markings are prohibited

When this mark appears, we need to be careful not to put our feet on the robot or climb on it. This will not only have a negative effect on the robot, but also may cause injury to the operator if he or she steps on the air.

7. Such a warning mark appears on the air outlet of the robot motor or control cabinet.

Pay attention to the high temperature marking

When this mark appears, we need to pay attention to the heat generated where this mark is affixed. In the case of heat, if you must touch the equipment due to unavoidable circumstances, you should prepare protective equipment such as heat-resistant gloves, otherwise it will cause burns to the workers

When engaging in related operations, we must pay attention to the relevant warning signs, and strictly follow the instructions of the relevant marks, so as to ensure the safety of operators and the robot body, and gradually improve the awareness of safety precautions and production efficiency.

Disclaimer: All content is only for learning and communication, if you operate by yourself and cause unpredictable problems, please bear the risk and consequences caused by the test.

———————— END ————————

News